The world of stainless steel is reflected in its manifold applications.

Inform yourself about the professional processing of stainless steel at Metabo.

1. Material removal – the first steps (opening up hot-rolled surfaces)

Before the steps of burnishing and polishing can commence, hot rolled

stainless steel surfaces must first have their very hard surface skin removed.

The skill is to "open up" the material in the first stage of the surface

preparation. Without doing so, further processing of the surface would be

near impossible.

Burnishing machine SE 12-115

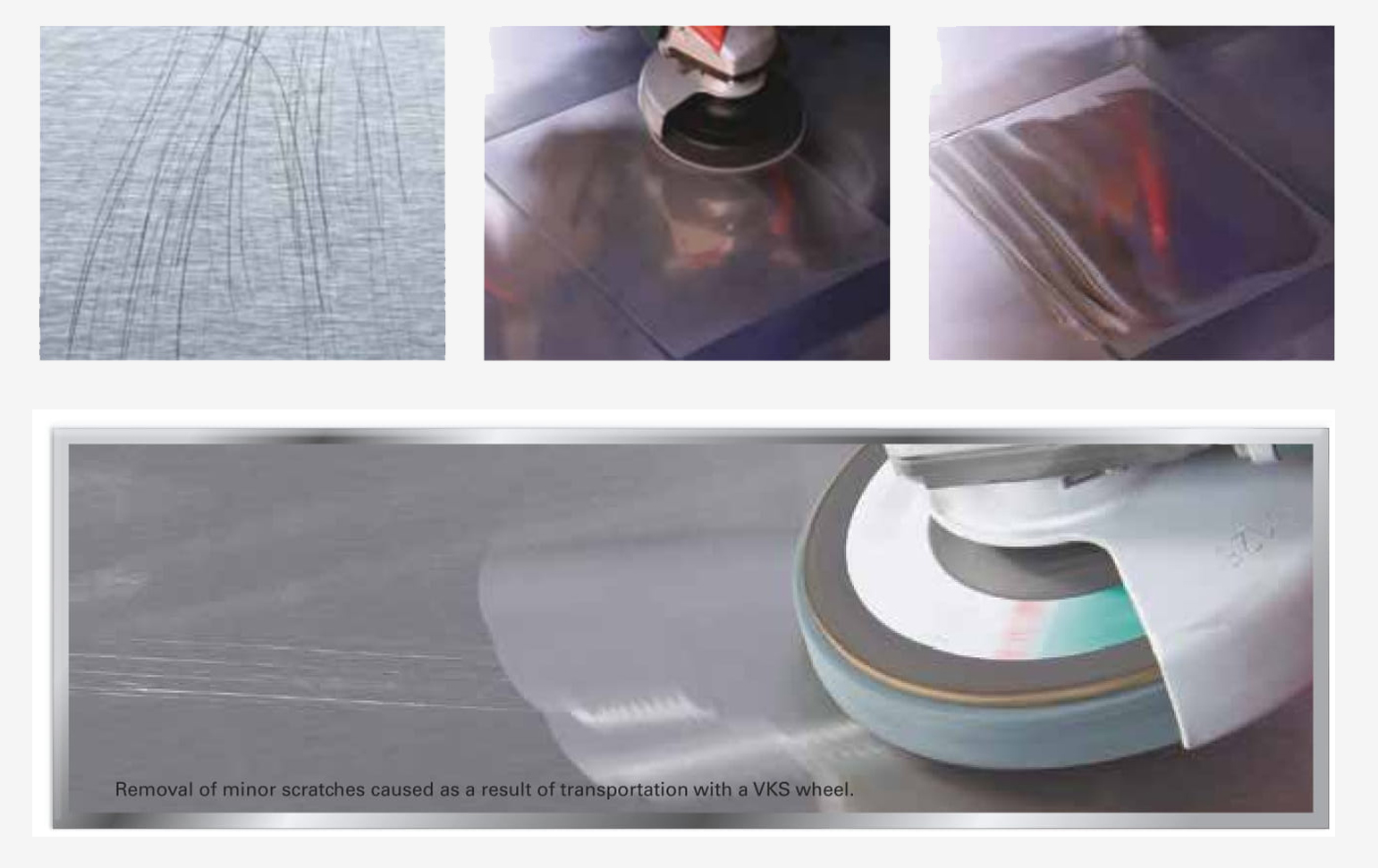

2. Removal of scratches on sheet steel

a. Removing minor scratches

.jpg)

b. Removing deep scratches

Angle grinder WE 14-125 Inox Plus

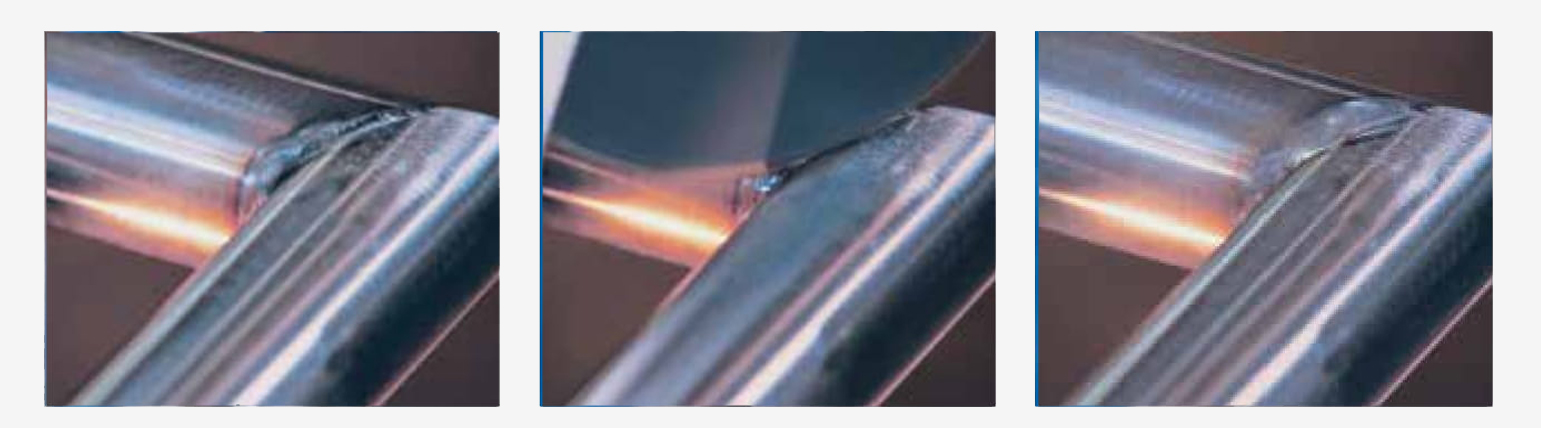

3. Grinding off welding seams

a. Removing a TIG weld seam on a straight handrail section

Pipe belt sander RBE 12-180

b. Removing a TIG weld seam on a bevel corner of a handrail

Angle grinder WE 14-125 Inox Plus

c. Removing a right angle weld seam on a handrail

Fillet weld grinder KNSE 12-150

Tip:

Match the disc profile to the weld profile before starting. Put a curved profile on the fleece compact disc VKS using the

profiling file to ensure that the disc matches the rounding of the welding seam.

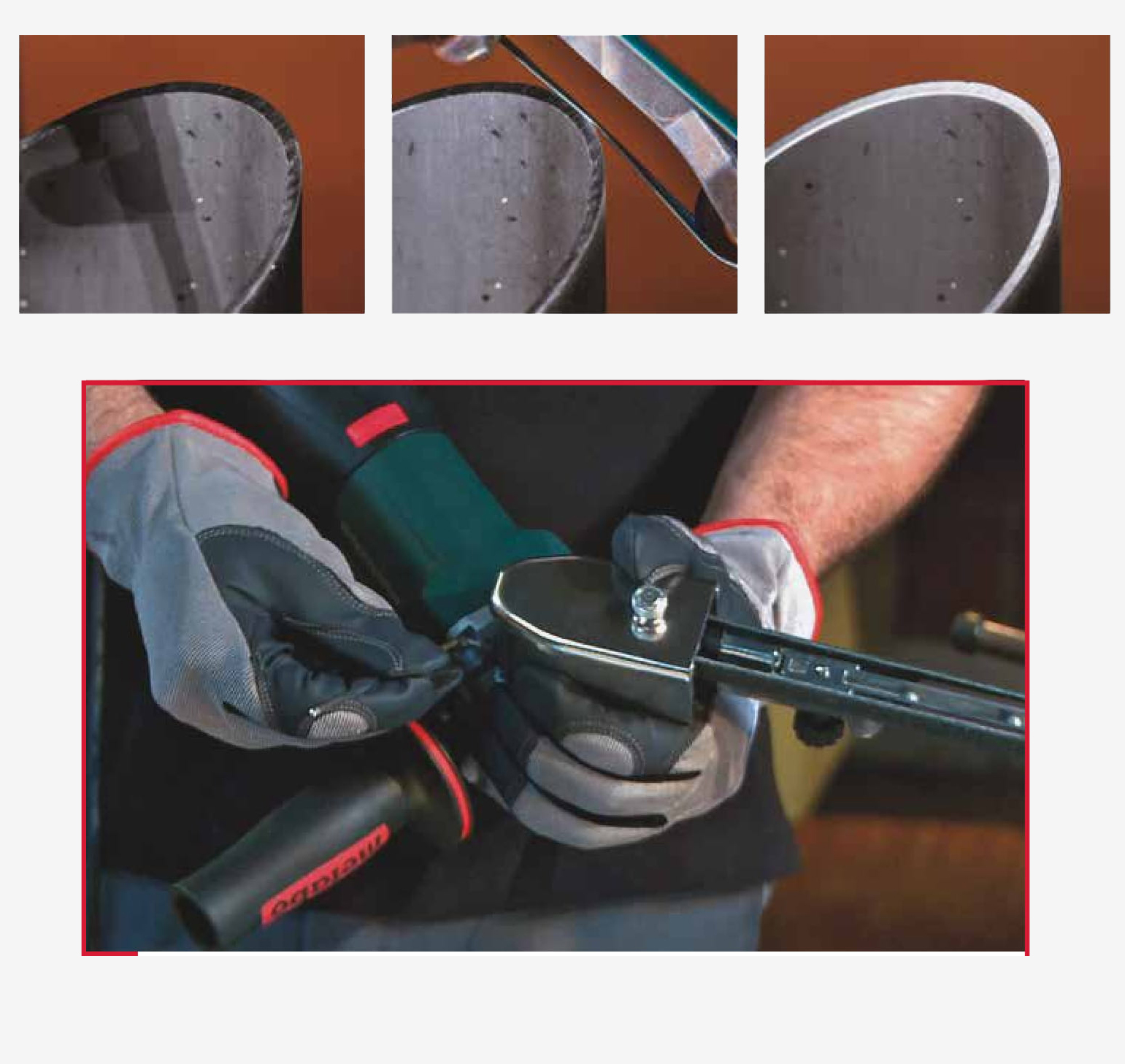

4. Deburring

Deburring a pipe

Tip:

With a choice of 4 sanding belt arms available you can always pick the right sized arm for the job.

These arms can also be rotated left and right, with an arc radius of about 270°.

Band file BF 9-90

ĐỌC THÊM The professional processing of stainless steel

Không có bình luận nào cho bài viết.